What are Concrete Y-Girders ?

- USAMA KHAN

- Dec 7, 2024

- 4 min read

INTRODUCTION

Concrete-type girders are a type of structural element commonly used in bridge engineering. Their unique shape, resembling the letter "Y," provides distinct advantages in terms of load distribution and structural efficiency.

These are closely related to the I-section girders and are used to dissipate the loads to the sub-structure i.e. piers all the way to the foundation.

This type of a shape is used to reduce material costs while achieving the same results as an I girder simultaneously.

Design Principle

Y-type girders are designed to efficiently distribute loads from the bridge deck to the supports. The design takes advantage of their geometry to minimize material use while maximizing strength and stability. They are primarily designed the same way as concrete post tensioned I-section bridges.

The design and construction of Y-type girders should adhere to the appropriate Building Codes / standards Requirements, which basically require the following for the design consideration:

Minimum reinforcement requirements.

Load factors and load combinations.

Design for shear and bending.

Durability considerations.

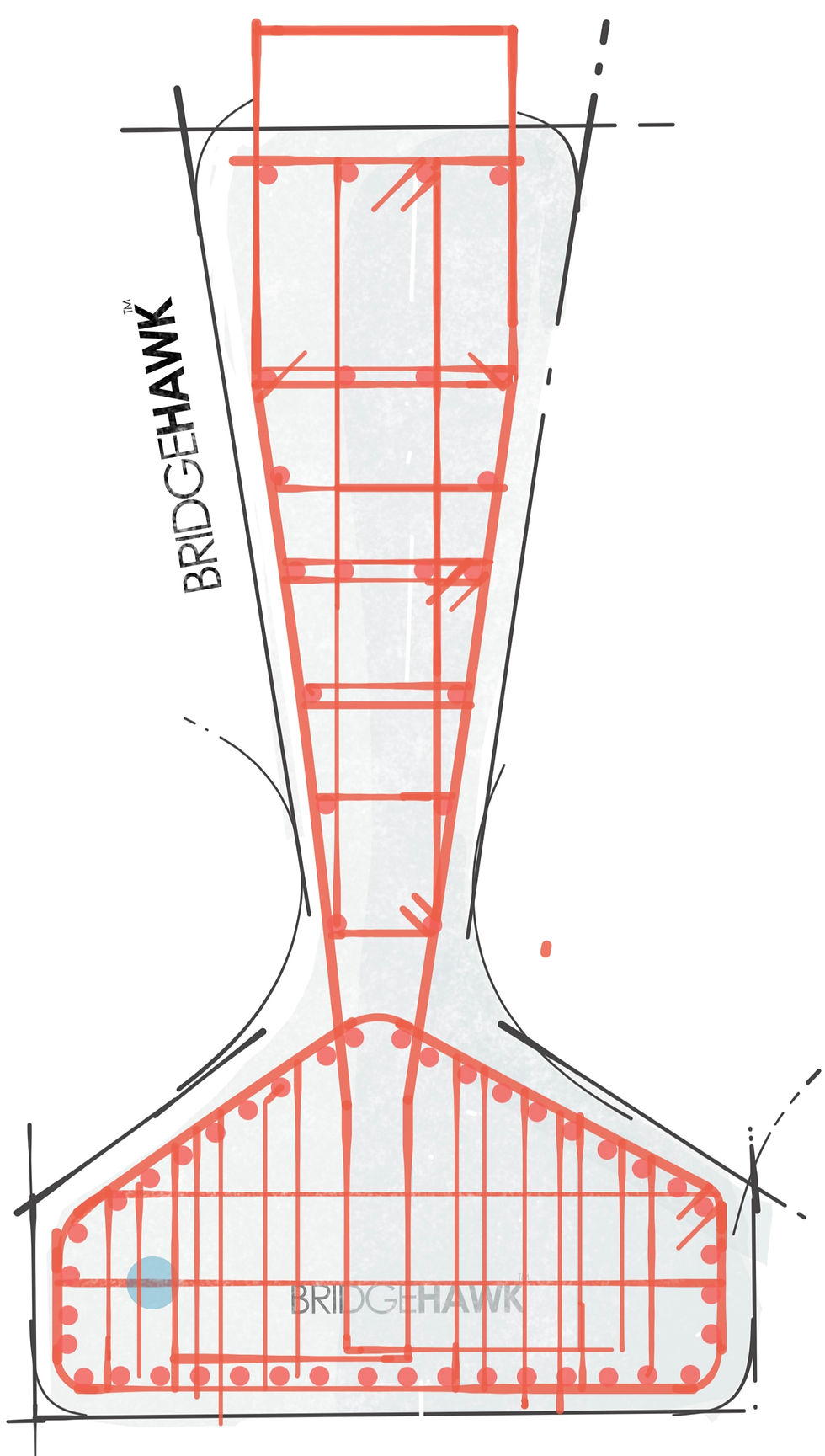

Rebar arrangement for a standard Y-girder

CONSTRUCTION

Types of Y-Type Girders

The Y-type girder can be categorized based on its preferred construction method.

Precast Y-Girders: Manufactured offsite in a yard where the shuttering arrangement is already in place and casted. It is later transported to the construction location safely.

Cast-in-Place Y-Girders: these types are constructed on-site, allowing for integration with other structural elements including the diaphragm and the deck.

The deck is constructed after the placement / construction of the girder and could be chosen to be either of the following:

Composite Decking: Often, a concrete slab is cast on top of the girders, with reinforcement ties connecting the deck to the girders to share load.

Precast Panels: In some constructions, precast concrete panels are placed on top of the girders to form the deck, allowing for rapid construction.

Utilities and Profiles: Integration of utilities (like water and electrical lines) can occur within or above the decking material for efficiency and aesthetics.

Post Tensioning

Post tensioning involves placing high-strength steel tendons within ducts in the concrete and then tensioning them after curing. This helps to counteract tensile forces and reduces cracking, ultimately enhancing the performance of the girder.

The y girders like their more common contemporary the I-section girders, also have the post tensioned strands. In most cases, pre-tensioning is also preferred. This choice of tensioning design is purely based on the design engineering discretion apart from other governing factors.

Supports

Supported by appropriate bearing systems and piers, they offer reliable performance in diverse environments. The type of supporting piers is mostly concrete piers. In a bridge, these girders are directly placed on bearings which might either be of the following types.

Elastomeric Bearings: Commonly used to provide flexibility and allow for movement due to temperature changes or seismic events. They accommodate rotations and horizontal movements while supporting vertical loads.

Pot Bearings: Often employed in larger applications, allowing for movement and adapting to differential settlements.

Advantages

Y girders offer several advantages over other girder shapes (like I-beams or box girders) in specific applications, primarily due to their geometry and material efficiency.

Material Efficiency: The Y-shape allows for a significant reduction in the weight of the girder, resulting in less material usage while maintaining strength. This efficiency can lead to lower construction costs.

Enhanced Load Distribution: The shape facilitates better load distribution, minimizing stress concentrations and enhancing stability across various load scenarios.

Aesthetics: Y-type girders can offer a more visually appealing structure, making them suitable for projects where aesthetics are a consideration.

Versatile Applications: Suitable for various span lengths and loads.

Disadvantages

Complex Construction: The unique shape may complicate construction and alignment.

Handling Issues: Precast elements can be challenging to transport and install due to their size and shape.

Applications

Y-type girders are relevant to the construction industry today and find most application in vehicular bridges and in other elevated viaducts in highways.

These girders can also be used for railway bridges. Their ability to handle significant vertical loads makes them suitable for rail applications, including but not limited to Heavy Freight Trains bridges, High-Speed Rail as these girders can support the additional loads encountered with rail transport to ensure stability and aerodynamics for such use cases.

Their use depends on regional preferences, project specifications, and structural requirements. In some areas, advancements in materials and design may have led to a preference for other girder types. Their selection ultimately depends on project-specific requirements, including load, span, and budget.

Subscribe to the #bridgehawk channel on Youtube

visit the official website for more bridge design resources

Hashtags

#bridges #bridgeengineering #civil #civil3d #civilengineeringworld #civilengineering #civilengineer #civilengineers #civilengineeringstudents #civilconstruction #civilengineeringdesign #civilengineeringdiscoveries #civilworks #civilengineeringlife #creativity #creativityskills #creativityisnow #bridges #bridgeengineering #bridgeconstruction #bridgedesign #bridgeinspection #bridge #bridgebuilding #structural #structuraldesign #structuralengineer #structures #structuralengineering #structuralanalysis #structuralmodeling #structuralsteel #structuralhealthmonitoring #3d #3dmodeling #3dartist #3drendering #3dmodel #girder #boxgirders #construction #concrete #steel #posttensioning

Comments